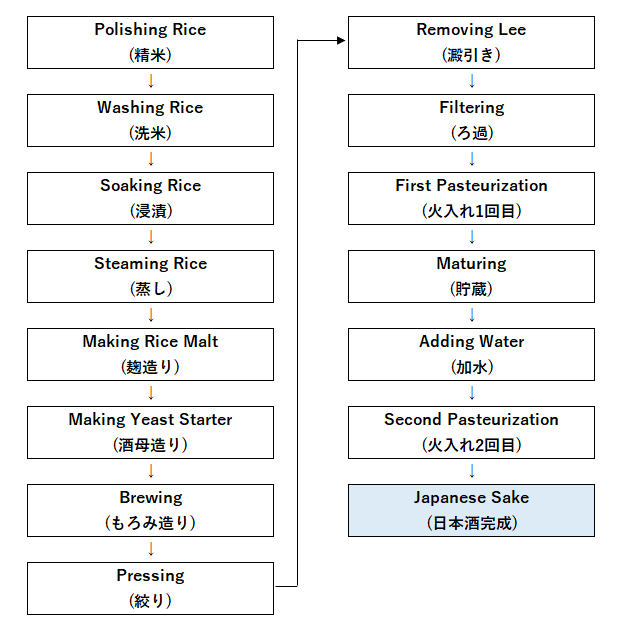

Brewing Process of Japanese Sake

Table of Contents

Brewing Process of Japanese Sake (Picture)

Polishing Rice

This is the first step of brewing Japanese Sake. Brewers have to remove the outer layer of brawn rice and expose the starchy core. Because the outer layer contains protein and lipid that cause unfavorable effects on brewing process. High class Japanese Sake, Dai-Ginjo-Shu, is used rice that is polished under 50%.

Washing Rice

After rice is polished, brewers wash it to remove the rice powder that is generated in polishing.

Soaking Rice

Brewers soak rice to contains moisture. This process is very delicate. Soaking time is controlled in seconds.

Steaming Rice

Steaming is a preparation for next step. The purpose is to make rice soft. It will help Koji mold dig into inside.

Making Rice Malt

Brewers sprinkle Koji mold on steam rice. It is stored in a special warm room to enhance Koji mold propagating.

Making Yeast Starter

Brewers put Rice Malt, steamed rice, water and yeast into a small tank and mix them. The purpose is to increase yeast. Lactic bacteria plays an important roll in brewing process. It prevents other bacteria increase. It is common that brewers add brewing Lactic bacteria. But, some use natural Lactic bacteria that hover in air. It is said that the flavor and taste of Japanese Sake depend on this process a lot.

Brewing

Brewers put Yeast Starter, Rice Malt, steamed rice and water into a large tank. But, tank is filled only 20%. On second day, they don’t do nothing. It helps yeast to increase. On third day, they add Rice Malt, steamed rice and water again. The adding volume is double of the first day. Last day, they add Rice Malt, steamed rice and water again. The adding volume is double of the third day. Brewers keep it for 2-4 weeks. Yeast Starter, Rice Malt, steamed rice and water ferment into Moromi.

Pressing

Once Moromi has been brewed, brewers separate into Japanese Sake and the remaining (Sakekasu). There are several methods for pressing.

Removing Lee

The Japanese Sake is preserved in a tank to sink lees. It is common that brewers use the supernatant part.

Filtering

Brewers filter the supernatant liquid by charcoal filter. Charcoal filter has a lot of small holes that traps unnecessary matters, like dead yeast.

First Pasteurization

Brewers heat Japanese Sake to around 65℃ quickly. The purpose of this process is to kill Lactic bacteria and yeast that remains in Japanese Sake. If they remain, they will spoil Japanese Sake stored in room temperature.

Maturing

Brewers store Japanese Sake in a tank during summer. This process mature and smooth the flavor and the taste.

Adding Water

This is last adjustment. Brewers add water to achieve the flavor and the taste image.

Second Pasteurization

Brewers heat Japanese Sake again. This process comes right before bottling. Some heat Japanese Sake before bottling. The other heat it after bottling. It depends on what flavor and taste brewers would like to represent.